The history of wood veneering originates in Ancient Egypt circa 3000 BC and continues into modern day woodworking. Historically, veneers were cut by hand until about the 1820’s where machines started to be used to cut the wood uniformly thin.

Nowadays most people think of wood veneers in one of two categories, thin laminates of wood found on cheap furniture, or intricate artistic veneer work found on custom made furniture. Veneering actually starts at the beginnings of recorded human history.

Veneer Making in Ancient History

Veneer is not a modern invention. History shows us that the ancient Egyptians were the first to saw thin boards from logs in order to best utilize the material. It only made sense. There were not many forests in the Egyptian controlled territories, so they had to stretch what wood they had.

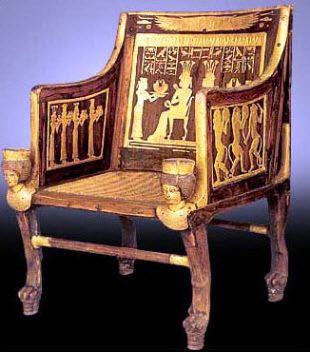

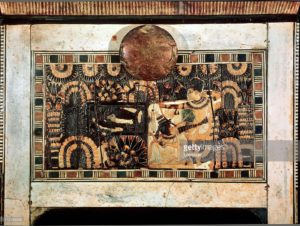

Old Kingdom Egyptians developed tools for shaving veneer from logs imported from Lebanon, Syria and Phoenicia. Thousands of years ago, incredible veneer work made of ebony and ivory was put into King Tut’s tomb in Egypt.

The history of veneer actually starts with the idea of conservation. Egypt consists mostly of desert, timber was rare and was highly valued as much as the precious stones that were used for the elaborate decoration of furniture.

As a result, veneers came into being where no large forests marked the landscape, but instead in a place where timber, as a raw material, was rare and its products were highly sought after.

The artifacts found in the tomb of King Tut show that although the woodworking techniques of that time were still quite rudimentary, people in this age people already knew how to reveal the inner natural beauty of wood.

The Ancient Egyptians also used wood veneers and created the first primitive versions of ‘plywood’ by taking the veneers and gluing them cross wise to each other.

Veneering Resurgence in France

Although the craft of veneering was practiced in classical antiquity, its use in Europe was sparse during the Middle Ages. It was revived in the 17th century, reaching its artistic height in France and spreading from there to other countries in European. Due to their love of using ebony, the French veneering craftsmen were known as ébénistes, although later that name became used for all woodworkers in France.

Veneer Resurgence During Renaissance

Re-sawing of wood into thin strips by hand is how veneer was made throughout most of history. However, veneer making dwindling during the European medieval period and only came back into fashion during the 17th century in France. More recently, although largely unappreciated, veneer construction has been found in furniture form appeared as early as the 16th. Century.

Eventually, the veneer techniques during the Renaissance became very sophisticated, using tiny pieces of exotic woods and burl grain to create intricate designs or lavish scenes, called marquetry or intarsia work. Much of the finest royal furniture for hundreds of years employed lavish veneer construction, using the finest species of wood and tiny pieces of burl or exotic grain.

Furniture manufacturing, originally elevated to artistic perfection by the great masters during the Renaissance and Baroque periods (as well as subsequent centuries), demonstrates how a simple need can become a cultural legacy, eventually developing into a form of expression for each era.

Victorian Era Furniture Making

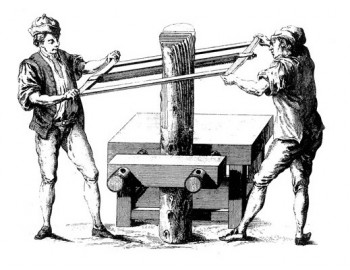

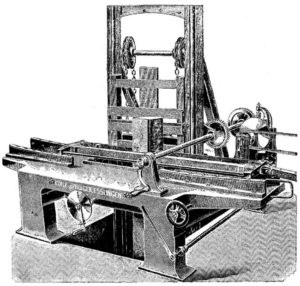

Beginning in the early 1800’s machines were invented to slice veneer, which were employed to make valuable woods like mahogany and walnut go further by gluing them to less prized species, like maple and birch. Around 1900, highly prized quarter-sawn or tiger oak was often veneered over regular cut solid oak.

The heritage of furniture manufacture has been refined and perfected in modern times in response to demand, and has grown from a handicraft into a highly mechanized industry. At the same time, veneer manufacture, although an industry, has remained very much a craft.

As tool and machine making became more sophisticated, the sawing of logs was replaced by the much more accurate of slicing with knives instead of sawing with blades.

Veneer Use Good & Bad

However, it was in the nineteenth century that veneering started to develop a bad reputation when some furniture manufacturers were using machine made veneers mainly as a method of covering up badly constructed furniture made of cheaper pine or poplar wood.

Eventually, new production techniques slowly gained acceptance and full scale veneer production developed into an industry in the 1950s.

Starting about 1970, industrial furniture manufacturers developed the technique of gradually making veneer thinner. Today, hardwood veneers are as thin as 1/64 of an inch! This modern veneer looks like typing paper, it is almost transparent, and can never be sanded, refinished or significantly touched up if damaged.

Veneered wall panels appeared in shops, restaurants, offices, banks, insurance companies and public building. Advanced manufacturing techniques and growing public awareness of the virtues of real wood veneers together with the need to conserve energy and resources have made the craft of veneering more popular than ever.

With the focus on conservation, using veneers to cover man made materials such as particle board and MDF has become a necessity if rare and hard to find species of trees want to be used at all in furniture making.

The making of veneer has very much surpassed the re-sawing of logs into strips, and the “peeling” of logs with machines. It is now a very sophisticated process that yields incredibly beautiful natural artwork that is hidden within a tree.

Wood Veneer Usage for All Woodworkers

The vast majority of veneers are used in factories for manufacturing panels and plywood. However, the advancement of technologies has also allowed the explosion of the use of wood veneers in the small shop setting. The low cost of veneers and substrates has made it possible for even the small time woodworker to use exotic veneers to enhance their woodworking pieces.

Hopefully this has been an enlightening read about the history of wood veneer.

Quick Q&A about Wood Veneer History

Who invented wood veneer?

Although many early civilizations have independently created veneer, the earliest examples that we have today exist from the Ancient Egyptians from over 5000 years ago.

When did wood veneer use become more widespread?

Wood veneers became more commonly used on furniture after the industrial revolution of the 1820’s in Europe. However it was still mainly used by craftsmen to build fine furniture.

When did wood veneer furniture start becoming cheap?

In the mid-nineteenth century, the ability to produce wood veneer from logs was vastly improved. Veneers were then used to cover cheaper substrates instead of using solid wood.